Looking for bespoke or flying end mesh?

Call now or click on 'Get A Quote' above if outside office hours.

For construction projects to be structurally sound and guaranteed to remain so throughout their intended lifespan, it’s essential that the build follows best practice guidelines in terms of lateral strength and integrity of materials.

To achieve the best possible strength for concrete elements of any build, whether commercial or domestic, reinforcement mesh is typically used, embedded within each poured concrete element.

This mesh, which is sometimes also called reinforcement fabric, plays a central role in almost every building project, whether that’s something as small as a domestic extension or as significant as a major infrastructure project such as a new bridge or a commercial multi-storey office build.

In this article, we look at a particular kind of reinforcement mesh, which is called flying end mesh, to understand the reasons why it makes sense to use this type of mesh and the circumstances when it is appropriate to use it.

The Basics of Reinforcement Mesh

Most people, even if they are not involved in the construction industry in any way, are familiar with what rebar is – the strong steel bar with a twist design that is used on building projects of all sizes (more info about rebar types and grades here).

Reinforcement mesh is a sheet material made up of rebar wires arranged in a lattice pattern of longitudinal and cross wires.

Depending on the intended use of the mesh, it is supplied as a square mesh, where the pitch between longitudinal and cross wires is equal, as structural mesh, where the cross wire pitch is twice that of the longitudinal wire pitch, and as long mesh, where the cross wire pitch is four times the longitudinal wire pitch.

Each of these mesh types have different applications, but the basic principle is the same for all of them – to provide lateral strength to concrete elements.

Both steel and concrete have very similar thermal expansion coefficients, which means that they work exceptionally well together to provide strength and durability.

When building poured-concrete elements, reinforcement mesh is laid out across the entire area to be covered in concrete, with every part of the slab needing to be covered (learn more about minimum thickness here). This often means that sheets of mesh are laid on top of one another, to guarantee that every part of the slab is given the same level of reinforcement.

How Does Flying End Mesh Fit In?

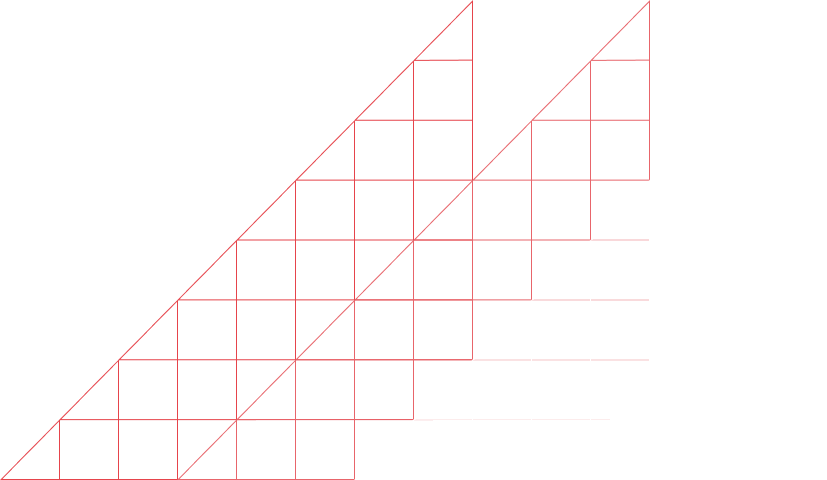

When panels of standard reinforcement mesh are overlapped, in order to provide the required level of reinforcement, they obviously stack up on top of one another and do not sit flat. On large slabs, up to four sheets could overlap in order to get the required reinforcement. Even with very careful tying in, that could add up to a significant lap build-up, which in turn means more concrete will be needed to get the required thickness of concrete, both below and above the mesh.

Flying end mesh offers a clever solution to this problem. The ‘flying end’ in the name of the mesh refers to the part at the end of the sheet of mesh, where one wire is missing. Flying end mesh could have a missing wire at the top of the sheet or along the side, to suit all layout needs. Because that end wire is missing, the sheet of flying end mesh can be slid into place next to a regular sheet (or another sheet of flying end mesh), without that overlap build-up that we explained earlier. The length of the flying end, which is known as the ‘lap’, is normally 400mm, which exceeds the minimum 350mm needed when overlapping traditional reinforcement mesh sheets. However, longer flying ends of 500mm are available, as are shorter flying ends of 200mm. By sitting level with the adjacent sheet of mesh fabric, the flying end mesh avoids any build-up, or congestion, and keeps the mesh layer at the same height across the entire slab.

Choosing The Right Flying End Mesh For Your Project

As with all types of rebar and reinforcement mesh fabrics, flying end mesh is supplied using a system of grades, which are suitable for different applications. Light-use applications such as garage floors require a concrete base that is typically around 100mm in thickness, and for these applications, an A grade mesh would be appropriate. A grade meshes have wires that are between 6 and 8mm diameter, depending on the specific grade. B grade meshes are much more substantial, and are designed for use in slabs that are up to 200mm thick. These meshes are for heavy duty applications. Obviously, it is essential to match the grade of flying end mesh with the grade of standard mesh that is being used on a project. If you’re not sure which to use, speak to a structural engineer, or give us a call for advice.

Flying end mesh is available with one flying end and side, or with flying ends on all four edges of the sheet. Sheets are normally exactly the same size as standard reinforcement mesh sheets, at 4.2m x 2.4m. This makes it particularly easy to calculate sheet requirements for a job, and keeps wastage to a minimum.

Why Use Flying End Mesh Instead of Standard Mesh?

It might be tempting to think that adding flying end mesh into a project just brings additional complexities, but in fact, the opposite is true.

Flying end mesh offers:

- faster layout times,

- less cutting of sheets; and,

- less wastage.

Checking the mesh layout is also simpler, and it’s much easier to ensure that the correct coverage has been achieved throughout. And of course, with flying ends handling all of the sheet to sheet joins, there is no congestion, and therefore no need to pour extra concrete. All of these benefits lead to significant cost savings, which can really mount up on larger projects. With at least one less wire per sheet, flying end mesh costs less than standard mesh too, which means there is a per sheet saving to be made as well.

Summary

Flying end mesh can solve the all too common problem of overlap congestion when laying out reinforcement mesh, and can save time and money along the way. It’s easy to use and there are simple calculators available to help you work out exactly how much flying end mesh you will need to cover any given area. Of course, our expert team is always on hand to offer practical help and advice when selecting all kinds of reinforcement mesh and related products.

Contact us today to discuss your next project and to find out how flying end mesh could make your job much simpler.