Enter slab dimensions, cover and spacings to get bar counts, total length, stock pieces, and cost. Laps/hooks excluded (use the Lap Length Calculator for that).

1) Units & Slab

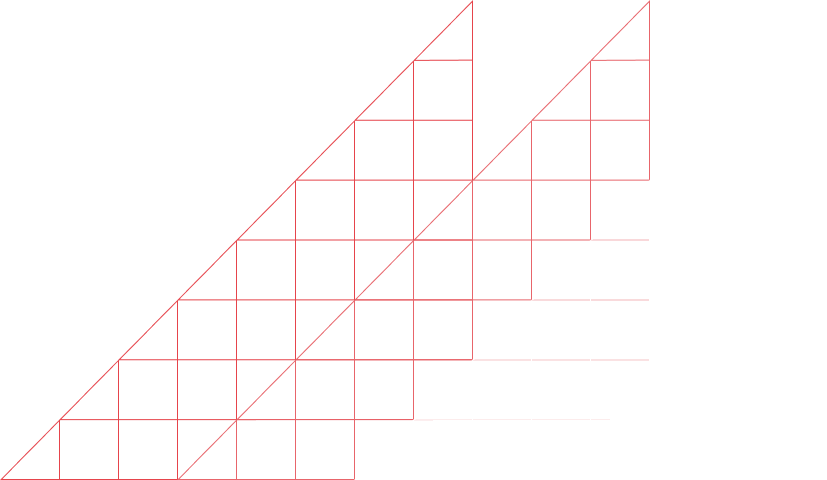

2) Rebar Spacing & Layout

3) Rebar Layers & Supplier

⚠️ Important: This calculator estimates rebar counts, bar lengths, grid coverage, stock pieces and cost based on uniform spacing and even edge cover. It does not account for laps, hooks/bends, openings, development/anchorage requirements, congestion, or code-specific minimums/maximums. All reinforcement must be designed and verified by a qualified structural engineer and checked against project drawings, specifications, and applicable codes. Heaton Manufacturing accepts no liability for site use of these values.

Instructions for Use

- Select your preferred measurement units (metres, millimetres, or feet).

- Enter the slab length, width, and edge cover.

- Input the rebar spacing across both slab width and length (centre-to-centre).

- Choose whether reinforcement is required in one or two layers.

- Set the waste allowance (%) and specify the stock length of rebar supplied.

- Enter your supplier’s price per unit (per metre or per piece).

- Review the calculated outputs, including bar counts, cut lengths, total rebar length, and cost estimate.

- Use results for estimation only. Confirm compliance with your structural engineer’s specification.

How to Estimate Rebar for Domestic Housing, Extensions, and New Builds (UK)

Estimating reinforcement steel (rebar) is essential when planning domestic concrete slabs and strip foundations. Use this guide for estimation and cost planning only. Final reinforcement design must comply with UK Building Regulations (Approved Document A – Structure) and the design standard Eurocode 2 (BS EN 1992-1-1), with detailing to BS 8666, and be confirmed by a structural engineer.

Instructions for Using the Calculator

- Select your measurement units (metres, millimetres, or feet).

- Enter slab length, width, and edge cover.

- Set rebar spacing in both directions (centre-to-centre).

- Choose one or two reinforcement layers.

- Enter waste allowance (%) and stock length (typically 6 m or 12 m).

- Input supplier price per unit (per metre or per bar).

- Review outputs for bar counts, cut lengths, total length, and cost.

- Disclaimer: Results are for estimation only—confirm with your structural engineer.

Regulatory Basis (UK)

Reinforcement for slabs and strip footings must satisfy Approved Document A – Structure and be designed to Eurocode 2: BS EN 1992-1-1. Minimum cover, spacing, lap lengths, and durability classes should be taken from Eurocode 2 (e.g., cover guidance in Table 4.4N) and detailed/scheduled to BS 8666.

Step 1 – Define Slab Dimensions

- Record finished length, width, and thickness.

- Set edge cover to protect steel (typically 25–40 mm for internal slabs; ≥50 mm for external/aggressive exposure per Eurocode 2).

Effective reinforcement dimensions (approx.):

<effective length> = <finished length> − 2 × <cover>

<effective width> = <finished width> − 2 × <cover>Step 2 – Determine Bar Spacing

- Common domestic spacings: 150–200 mm c/c.

- Eurocode 2 limit: maximum spacing is the lesser of 3 × slab thickness or 400 mm.

Step 3 – Calculate Bar Counts

Calculate bars in each direction using the effective span and chosen spacing. Round up to the next whole bar.

Number of bars = (Effective span ÷ Spacing) + 1Step 4 – Account for Layers

- Single layer: often adequate for lightly loaded ground-bearing slabs.

- Two layers (top + bottom): for suspended slabs or heavier loads (e.g., garage slabs, slabs supporting walls).

Step 5 – Add Waste and Laps

Waste allowance for cutting/handling: typically 5–10 %.

Lap lengths for continuity (Eurocode 2): commonly 40–50 × bar diameter in tension, depending on concrete class and bond conditions.

Example tension lap (12 mm bar) ≈ 40–50 × 12 mm = 480–600 mmStep 6 – Match Stock Lengths

UK stock lengths are typically 6 m or 12 m. Optimise cutting to minimise off-cuts and consider on-site handling/transport constraints.

Step 7 – Total Length and Weight

Total rebar length = Σ (bar count in each direction × respective cut length)

Indicative mass per metre (approx.): 10 mm = 0.617 kg/m, 12 mm = 0.888 kg/m, 16 mm = 1.58 kg/mStep 8 – Verification

- Check against engineer’s drawings/specification.

- Confirm bar diameters, cover, spacing, and laps per Eurocode 2 and project details.

Worked Example (Single Layer)

Slab: 5.0 m × 3.0 m, thickness 150 mm, cover 50 mm, spacing 200 mm.

Effective length = 5.0 − 2 × 0.05 = 4.90 m

Effective width = 3.0 − 2 × 0.05 = 2.90 m

Bars across width = (2.90 ÷ 0.20) + 1 = 15.5 → 16 bars

Bars across length = (4.90 ÷ 0.20) + 1 = 25.5 → 26 bars

Total (single layer) = 42 bars

Cut lengths: length bars ≈ 4.90 m, width bars ≈ 2.90 m

Total steel length (no laps) ≈ 153.8 m

+ 5% waste ≈ 161.0 mKey References

- UK Building Regulations — Approved Document A: Structure.

- Eurocode 2: BS EN 1992-1-1 — Design of concrete structures.

- BS 8666 — Scheduling, dimensioning, bending, and cutting of reinforcement.

Summary

- Measure slab and apply covers to get effective dimensions.

- Select spacing within Eurocode 2 limits (typ. 150–200 mm c/c).

- Compute bar counts in both directions and consider one vs two layers.

- Add waste and lap allowances; optimise against stock lengths.

- Verify against the structural engineer’s design before ordering.

Important: This information is for estimation purposes only and does not constitute a design. Always consult and follow your structural engineer’s specification.