Starter bars are lengths of reinforcement steel cast into, or fixed into, a concrete element to allow structural continuity with a future pour or masonry element. They are most commonly used to transfer loads between footings and walls, slabs and columns, or bases and retaining walls.

In practice, the bar size, spacing, embedment depth, and fixing method are design decisions, typically set by the structural engineer and assessed by Building Control at inspection stage. The role of the installer is to ensure those requirements are followed accurately on site.

Why starter bars exist (load transfer, not “joining”)

Starter bars are not simply a way of tying two elements together. Their primary function is to ensure continuity of reinforcement, allowing loads to be transferred safely from one element into another without relying solely on concrete bond or friction.

Typical scenarios include:

- Vertical load transfer from masonry or concrete walls into foundations

- Moment and shear transfer in retaining walls

- Continuity of reinforcement between phased concrete pours

Where reinforcement is interrupted – for example, between a footing pour and later wall construction – starter bars provide that continuity.

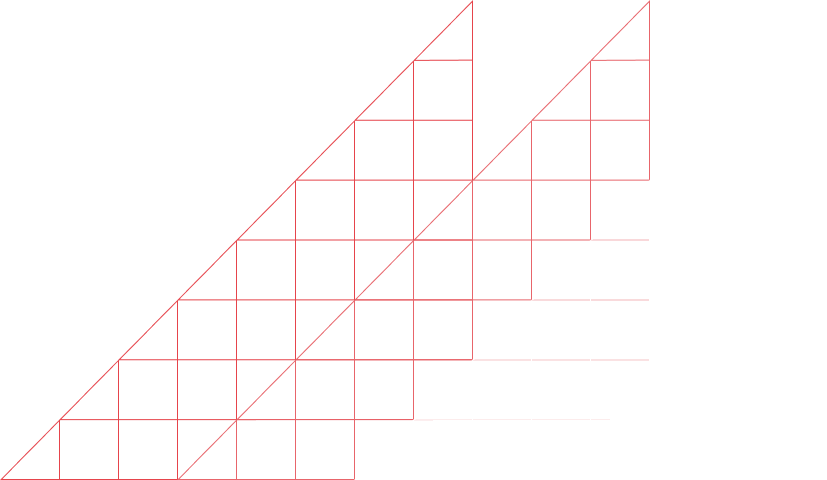

Typical forms of starter bar

Straight and L-shaped bars

The most common starter bars are straight or L-shaped, cut and bent to suit the reinforcement schedule. These are normally supplied as part of a wider cut-and-bent rebar package and installed during the initial concrete pour.

This approach offers the highest level of certainty, as:

- Bar geometry is fixed

- Embedment is cast in

- No post-installation fixing is required

This is generally the preferred solution where programme allows.

Mechanical coupler starter systems

Mechanical starter bar systems use threaded couplers to allow a second bar to be installed once the initial concrete element has cured. A female coupler is cast into the first pour, with the mating bar installed later using a calibrated wrench.

These systems are often used where:

- Protruding bars would create access or safety issues

- Phased construction is required

- Dimensional accuracy is critical

They are widely accepted, provided the system is approved for the specified bar grade and load conditions.

Resin-anchored starter bars (post-installed)

Where a new element needs to connect into an existing concrete structure, starter bars can be installed by drilling and resin anchoring.

This method is common – and also the most inspection-sensitive.

Key points that matter in practice:

- Hole diameter and depth must match the resin system approval

- Holes must be properly cleaned (blow–brush–blow)

- Bars must be installed to the full embedment depth

- Cure time must be respected before loading

Building Control will typically expect:

- A CE- or ETA-approved resin system

- Installation in line with manufacturer instructions

- Engineer confirmation where loads are significant

Resin anchoring is not a “quick fix” and should never be treated as interchangeable with cast-in bars without design approval.

Bar grade, durability, and standards (what inspectors expect)

In the UK, starter bars are typically supplied in ribbed high-yield reinforcement, commonly B500 grade, in line with current reinforcement standards.

While the detailed structural design is outside the scope of this page, in practice starter bars interact with several key standards:

- BS 8666: bar shapes, bending dimensions, and scheduling

- Eurocode 2 (BS EN 1992): anchorage, lap lengths, and load transfer

- PD 6687: UK guidance on concrete design and detailing

For exposed or aggressive environments, additional protection, such as increased cover or coated reinforcement, may be required.

Installation considerations that commonly cause problems on site

Based on real-world site and inspection experience, issues most often arise from:

- Starter bars being cut down after pour to “make things fit”

- Incorrect spacing carried through from drawings without checking site conditions

- Bars left exposed for extended periods without protection

- Resin anchors installed without proper hole preparation

None of these are material issues, they are process and workmanship issues.

Safety on site — protruding reinforcement

Exposed starter bars present a clear site safety risk, particularly during early construction phases. Best practice is to:

- Fit protective rebar caps to all exposed ends

- Maintain clear visibility around protruding bars

- Remove or bend bars only where approved

Hooked bars can reduce impalement risk but do not replace the visibility benefits of protective caps, particularly on busy sites.

Where starter bars are most commonly used

Starter bars are routinely specified in:

- Foundations and ground beams supporting masonry walls

- Reinforced concrete columns and cores

- Retaining walls tied into base slabs

- Phased concrete construction

In retaining wall applications in particular, attention must also be paid to:

- Cover

- Drainage

- Corrosion protection

These factors are assessed as part of the overall wall design, not in isolation.

Final note on specification and supply

Starter bars are a small component with a large structural role. Correct bar size, shape, grade, and installation method should always be confirmed against the engineer’s details before work begins.

Where starter bars form part of a wider reinforcement schedule, early coordination between design, supply, and installation helps avoid delays and rework.