Flying end mesh is a modified reinforcement mesh sheet with one wire removed to eliminate lap build-up. It allows adjacent sheets to sit level, reducing concrete usage, speeding up installation and improving consistency across large slabs. It’s ideal for wide floor areas where standard mesh overlaps would otherwise stack and create unnecessary height and cost.

Looking for bespoke or flying end mesh?

Call now or click on 'Get A Quote' above if outside office hours.

For construction projects to be structurally sound and guaranteed to remain so throughout their intended lifespan, it’s essential that the build follows best practice guidelines in terms of lateral strength and integrity of materials.

To achieve the best possible strength for concrete elements of any build, whether commercial or domestic, reinforcement mesh is typically used, embedded within each poured concrete element.

This mesh, which is sometimes also called reinforcement fabric, plays a central role in almost every building project, whether that’s something as small as a domestic extension or as significant as a major infrastructure project such as a new bridge or a commercial multi-storey office build.

In this article, we look at a particular kind of reinforcement mesh, which is called flying end mesh, to understand the reasons why it makes sense to use this type of mesh and the circumstances when it is appropriate to use it.

Update for 2025/26:

Modern reinforcement mesh in the UK is produced in accordance with BS 4449:2005, typically using B500A wire, and is supplied with CE or UKCA conformity depending on the mill. These standards ensure consistent steel quality and compatibility with Eurocode 2 design requirements, and they apply equally to flying end mesh.

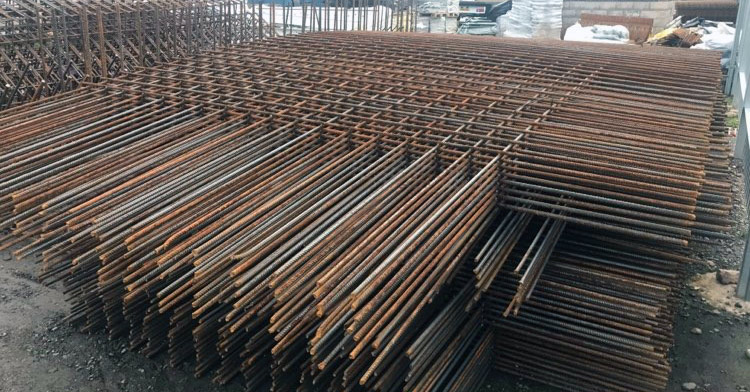

The Basics of Reinforcement Mesh

Most people, even if they are not involved in the construction industry in any way, are familiar with what rebar is – the strong steel bar with a twist design that is used on building projects of all sizes (more info about rebar types and grades here).

Reinforcement mesh is a sheet material made up of rebar wires arranged in a lattice pattern of longitudinal and cross wires.

Depending on the intended use of the mesh, it is supplied as a square mesh, where the pitch between longitudinal and cross wires is equal, as structural mesh, where the cross wire pitch is twice that of the longitudinal wire pitch, and as long mesh, where the cross wire pitch is four times the longitudinal wire pitch.

Each of these mesh types have different applications, but the basic principle is the same for all of them – to provide lateral strength to concrete elements.

Both steel and concrete have very similar thermal expansion coefficients, which means that they work exceptionally well together to provide strength and durability.

When building poured-concrete elements, reinforcement mesh is laid out across the entire area to be covered in concrete, with every part of the slab needing to be covered (learn more about minimum thickness here). This often means that sheets of mesh are laid on top of one another, to guarantee that every part of the slab is given the same level of reinforcement.

Clarification on Mesh Grades:

Mesh grades such as A193, A252, A393 refer to the mesh specification (wire diameter × spacing).

They do not refer to the steel’s ductility class (B500A/B/C).

This distinction matters because flying end mesh must always match the mesh grade used elsewhere on the project.

How Does Flying End Mesh Fit In?

When panels of standard reinforcement mesh are overlapped, in order to provide the required level of reinforcement, they obviously stack up on top of one another and do not sit flat. On large slabs, up to four sheets could overlap in order to get the required reinforcement. Even with very careful tying in, that could add up to a significant lap build-up, which in turn means more concrete will be needed to get the required thickness of concrete, both below and above the mesh.

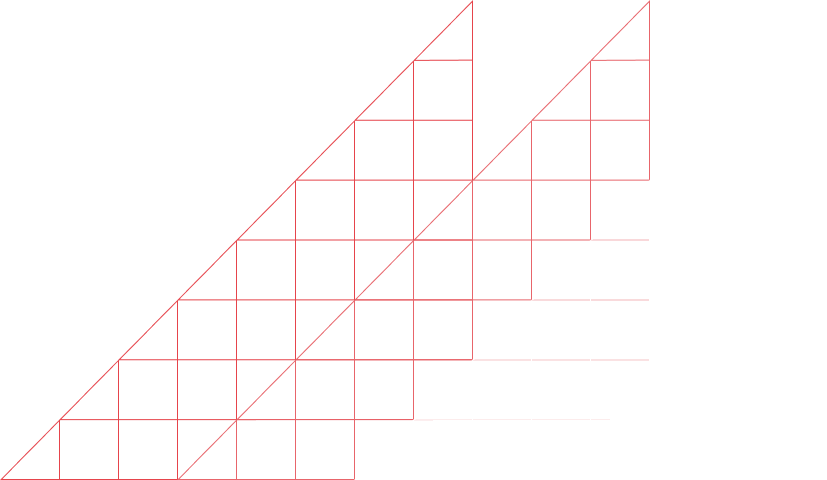

Flying end mesh offers a clever solution to this problem. The ‘flying end’ in the name of the mesh refers to the part at the end of the sheet of mesh, where one wire is missing. Flying end mesh could have a missing wire at the top of the sheet or along the side, to suit all layout needs. Because that end wire is missing, the sheet of flying end mesh can be slid into place next to a regular sheet (or another sheet of flying end mesh), without that overlap build-up that we explained earlier. The length of the flying end, which is known as the ‘lap’, is normally 400mm, which exceeds the minimum 350mm needed when overlapping traditional reinforcement mesh sheets. However, longer flying ends of 500mm are available, as are shorter flying ends of 200mm. By sitting level with the adjacent sheet of mesh fabric, the flying end mesh avoids any build-up, or congestion, and keeps the mesh layer at the same height across the entire slab.

Updated Lap Length Guidance:

Traditional reinforcement mesh normally uses a minimum lap of 350 mm, but in current UK practice many engineers specify 375–400 mm, depending on bar diameter and Eurocode 2 detailing. Standard flying end laps of 400 mm therefore exceed most design requirements, with 200 mm and 500 mm variants available for specific applications.

Sustainability Considerations:

Many UK mills now manufacture reinforcement mesh — including flying end sheets — using electric arc furnace (EAF) steel. This can reduce embodied carbon compared with traditional blast-furnace routes. It doesn’t change the performance of the mesh, but it’s increasingly requested on modern projects, particularly where sustainability reporting is required.

Choosing The Right Flying End Mesh For Your Project

As with all types of rebar and reinforcement mesh fabrics, flying end mesh is supplied using a system of grades, which are suitable for different applications. Light-use applications such as garage floors require a concrete base that is typically around 100mm in thickness, and for these applications, an A grade mesh would be appropriate. A grade meshes have wires that are between 6 and 8mm diameter, depending on the specific grade. B grade meshes are much more substantial, and are designed for use in slabs that are up to 200mm thick. These meshes are for heavy duty applications. Obviously, it is essential to match the grade of flying end mesh with the grade of standard mesh that is being used on a project. If you’re not sure which to use, speak to a structural engineer, or give us a call for advice.

Flying end mesh is normally supplied with a single flying end, or a flying end plus one flying side for specific layouts. Options with flying ends on all four sides do exist but are rarely required and generally used only on bespoke reinforcement designs.

Mesh Sheet Sizes:

Flying end mesh is available in the same dimensions as standard reinforcement mesh, typically:

Standard sheets: 4.8 m × 2.4 m

Merchant-size sheets: 3.6 m × 2.0 m

Mini sheets: 1.2 m × 2.4 m (industry term, not a formal standard)

This makes estimating material quantities and avoiding wastage much easier.

Why Use Flying End Mesh Instead of Standard Mesh?

It might be tempting to think that adding flying end mesh into a project just brings additional complexities, but in fact, the opposite is true.

Flying end mesh offers:

- faster layout times,

- less cutting of sheets; and,

- less wastage.

Checking the mesh layout is also simpler, and it’s much easier to ensure that the correct coverage has been achieved throughout. And of course, with flying ends handling all of the sheet to sheet joins, there is no congestion, and therefore no need to pour extra concrete. All of these benefits lead to significant cost savings, which can really mount up on larger projects. With at least one less wire per sheet, flying end mesh costs less than standard mesh too, which means there is a per sheet saving to be made as well.

When Flying End Mesh Is Not the Best Option

Although flying end mesh solves overlap congestion in most slab layouts, there are situations where it is not typically used:

- Heavily congested slabs with dual reinforcement layers where the engineer requires full bar continuity

- Small patch repairs where full mesh sheets aren’t needed

- Architectural or bespoke RC elements requiring complex bar detailing

- Where the engineer has explicitly specified traditional fabric laps for structural reasons

For the majority of ground-bearing and suspended slabs, however, flying end mesh remains a practical and cost-effective solution.

Summary

Flying end mesh solves the common problem of lap build-up when laying reinforcement mesh across large slab areas, keeping the steel layer level and reducing the concrete volume required. Modern sizes, lap options and the availability of EAF-produced steel make it a versatile option for both domestic and commercial projects. If you’re deciding whether flying end mesh is suitable for your design, our team can help you match mesh grades, lap requirements and sheet sizes to your project specification.

Frequently Asked Questions

What is flying end mesh?

Flying end mesh is reinforcement mesh with one longitudinal or cross wire intentionally removed, allowing sheets to overlap without creating lap build-up. This keeps the mesh layer level and reduces the amount of concrete required.

Why use flying end mesh instead of standard reinforcement mesh?

Flying end mesh avoids height build-up at overlaps, speeds up installation, reduces waste, simplifies layout checks and typically lowers concrete volume. On large slabs, avoiding multiple stacked overlaps can make a significant difference to time and cost.

How long is the flying end lap on flying end mesh?

The standard flying end lap is 400 mm, exceeding the minimum lap lengths normally required for A and B mesh. Options such as 200 mm or 500 mm flying ends are available for specific layout requirements.

Is flying end mesh compliant with UK standards?

Yes. Mesh used for reinforcement in the UK is generally manufactured to BS 4449:2005 using B500A wire and supplied with CE or UKCA conformity depending on the mill. Flying end mesh follows these same standards.

What sizes does flying end mesh come in?

Flying end mesh is available in the same dimensions as standard mesh sheets, typically:

• 4.8 m × 2.4 m (standard sheets)

• 3.6 m × 2.0 m (merchant-size)

• 1.2 m × 2.4 m (“mini” sheets, a non-standard industry term)

These sizes make estimating coverage straightforward and reduce wastage.

Can flying end mesh be used with standard mesh?

Yes. Flying end mesh is designed to integrate seamlessly with standard A or B grade mesh. It’s essential that the same mesh grade is used throughout (e.g., A393 with A393, A252 with A252).

Does flying end mesh cost more or less than standard mesh?

Typically, flying end mesh costs slightly less per sheet because it contains one fewer wire. Its main cost saving, however, comes from reducing concrete volume and labour time.

When should flying end mesh not be used?

Flying end mesh is not typically used in:

• heavily congested dual-layer reinforcement

• architectural or non-linear RC elements

• areas where full wire continuity is required

• small patch repairs

It is most suited to wide slab layouts where lap build-up is a problem.

What grade of flying end mesh do I need?

For light-duty slabs (e.g., garages), A-grade mesh is usually appropriate. For heavier-duty slabs (up to around 200 mm thick), B-grade mesh is common. The flying end mesh must always match the grade of the main mesh being used.

Is flying end mesh suitable for sustainable or low-carbon projects?

Yes. Many UK mills now produce reinforcement mesh — including flying end mesh — using electric arc furnace (EAF) steel, which offers reduced embodied carbon. This does not affect structural performance.

Does flying end mesh reduce concrete usage?

Yes. Since the sheets sit flat without build-up, the slab thickness stays consistent, reducing the extra concrete needed to cover stacked overlaps.

Can I get flying end mesh with more than one flying edge?

Yes. It’s usually supplied with one flying end or a flying end plus one flying side. Flying ends on all four edges are possible for bespoke designs but are rarely required.